Since August 2016 Japanese government has been promoting work style reforms. We should think seriously that work style reforms is equal to productivity improvement. Realizing less working hours could result in higher productivity.

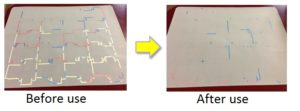

In this respect demands on shorter make-ready time in a flatbed die cutting operation is very high. is the first product in the world that corrects the unbalanced flatbed die-cutter and can reduce make-ready time. It is installed on more than 250 die-cutters in Japan.

On 7th Oct. 2017 a factory tour observing the installation of “PRESS BALANCE SYSTEM” ,held in in Aichi Prefecture, Japan. It will be demonstrated there how difficult to maintain the balance of platen for long and how effective “PRESS BALANCE SYSTEM” works.

The organizer is the company COUNTER PLATE JAPAN. Co-hosts are the company NAKAYAMA and YUUKOHSHA CITO TRADING.

We will report it again!